Box Gutter Being Lined With EPDM Single Ply Rubber

The builder has built a new side extension and we left the decking open ready to lay a new single ply EPDM rubber flat roof.

RubberBond EPDM single ply rubber roofing is, in fact, gas permeable and the main adhesive used to lay it is water-based. The moisture in the decking and from the adhesive will evaporate through the EPDM rubber. However it is good building practice to lay a new roof covering only on a dry roof, and in this case the roof was allowed to dry before laying.

This photo shows that the builder has lined the sides of the parapet walls, ready to receive the EPDM rubber single ply. This is an option as the open brickwork could either have been rendered or left open. However by leaving it open, the finished look of the job would have been compromised, so for not much more cost, rendering the brickwork makes the EPDM rubber roof look superb.

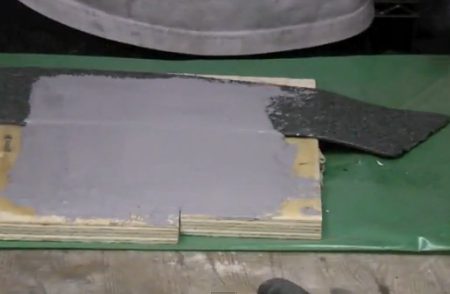

The EPDM single ply Rubber is being set out here for laying. You can see that joints will be minimal.

In this photo the EPDM single ply rubber has been dressed up the parapet walls and over the decking. It has been glued into position and the internal corner is being dressed, ready for finishing. By dressing the corner in this way there is no possible way that the corner can leak, even before it has been finished, as there is no open cut at decking level.

The EPDM will be dressed over the top of the surrounding parapet walls, ready for coping stones to be laid. There is no need for any lead or any expansion joints.

The EPDM rubber is very flexible and lends itself to being dressed up and around most corners. The large sheets minimise joints and this cuts down on labour costs.

The decking and all the edges of the EPDM Rubber have now been glued down. The final patching is about to take place, and as you can see, the flat roof is really taking shape.

This is the finished EPDM single ply box gutter, ready for the builder to tile the pitched roof around the skylights. Coping stones will also be set onto the parapet wall.

Comments (4)

Wish to use your product,for new box guttering,would like to know more about them,as how to bond it down.

This roof we used rubber bond EPDM rubber bond has a fleece back and he’s probably not only the most expensive EPDM rubber on the market that the best, unfortunately, these days we don’t get to use it that much as the customers really don’t like the price it’s probably twice the price of any other rubber on the market

Hi, I heard about something called Russ tape. Did you use this on the box gutter? Does it have to be used on all vertical 90 degree up stands or is it optional? Should it be used in a box gutter? I am worried about the mechanical fixing.

Thank you very much.

Emil

Russ tape is supposed to be used on roofs that are over 100 m² it’s to allow some kind of expansion and contraction of the EPDM rubber. No we didn’t use russ tape on the above roof